Introduction

Architectural drawings

Introduction

While studying mathematics

it can often happen that although the calculations have been made, we have not

thought about how we can use the aquired information in real life. One of such

fields where we don’t think it relates to our daily life and work is calculating

geometrical bodies (area, volume , angles ).

In practice , however, it

is of great importance . For example in piece work we must be able to calculate

our wage (surfaces, volumes ). Also when ordering materials we must be able to

calculate the volume of different objects ( rectangulars , triangles , pyramids

, cylinders , etc .).

In order to plan ahead it

is necessary to have the architectural drawings . If you ask the question why

does a builder need drawings, it might have different answers.

But one of the main

reasons is for the builder to get an idea of the planned building

. Namely , if you start building , it is possible to install an object in

nature on the basis of the drawing; through pre- design we obtain a

thoughtfully planned and meaningful result that has a predetermined shape and

size.

When using professional

construction workers to build a structure, the contractor can clearly convey

their wishes and vison of the planned structure through the project drawings.

All these activities will take place in everyday life through

simple mathematical operations . Therefor this study material is designed to

complement Your math studies through practical examples.

Standards

Since

nowadays many large collaborative projects and buildings become international

objects, it is increasingly more important that the drawings can be understood

by all the involved partners the same way, since a project drawing can include

a lot of symbols and meanings that are not universally agreed upon.

In the

interest of clarity, the international standard (ISO – the

International Organization for Standardization) has been created but next to them local national

standards apply that regulate the cooperation between builders and contractors

in a country. There is also European Standards ( EN) and standards

of the Republic of Estonia ( EVS - Estonian Centre for Standardization ). The

aim of the standards is for all the involved partners to understand the laws,

rules and symbols used in the process of construction or production in the same

way.

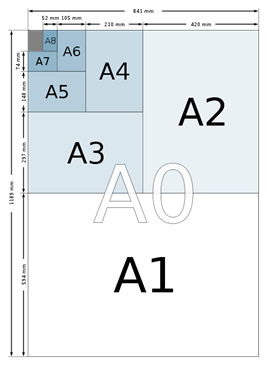

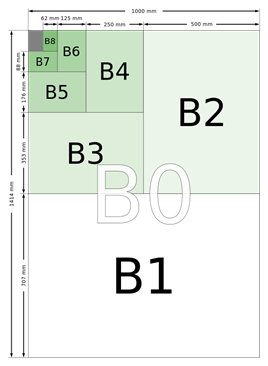

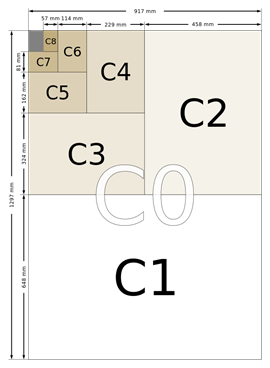

For paper sizes one of the best-known standards

is ISO 216. This standard defines 3

paper sizes “A” , “B” and “C”. Series “C” is used for envelopes. The

standardized paper sizes were first introduced in 1922 in Germany and are called

DIN 476 in Germany. This evolved into the international metric system that provides a universal

understanding of the sizes and measurements used in a drawing. As can be seen

in the figure below the letters A , B , or C with a number behind them, are

used to characterize the size of the paper format.

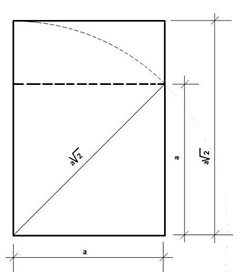

Paper in

the „A“ series format has a 1:√2 aspect ratio. It is known that √2 is an

irrational number (when rounded equals 1: 1.4142 ) . The result is rounded to the nearest millimetre. The

most frequently used of this series is the size A4 which is 210 mm × 297 mm

As we all know, ![]() is used to calculate the diagonal of a square. The same

principle is used to calculate the width and length of the “A” series paper

format.

is used to calculate the diagonal of a square. The same

principle is used to calculate the width and length of the “A” series paper

format.

For example, if we take the A4 format

, where a = 210 mm then ![]() = 296 , 98

≈ 297 mm

= 296 , 98

≈ 297 mm

The English language world uses its approximate the " Letter "

format, with the dimensions 216 x 279.

(which we might come across while printing on a computer)

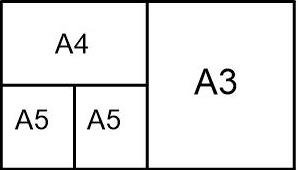

The number behind the letter represents an exact size also known as the

format. The smallest possible number is 0, but contrarily it is the biggest

possible format with the measurements 841 x 1189 mm. A0 is defined so that it has an area of 1 square metre, prior to rounding.

Successive

paper sizes in the series (A1, A2, A3, etc.) are defined by halving the

preceding paper size.

The B

series is defined as a subsidiary series of sizes obtained by placing the geometrical

means between adjacent sizes of the A series in sequence. To get the size of B1

the geometric mean of A1 and A0 is taken.

The C

series formats are geometric means between the B series and A series formats

with the same number (e.g., C2 is the geometric mean between B2 and A2). For

example, if an A4 page is folded in half so that it is A5 in size, it will fit

into a C5 envelope (which will be the same size as a C4 envelope folded in

half).

|

|

A- |

B- |

C- |

|

0 |

841 × 1189 |

1000 × 1414 |

917 × 1297 |

|

-1 |

594 × 841 |

707 × 1000 |

648 × 917 |

|

-2 |

420 × 594 |

500 × 707 |

458 × 648 |

|

-3 |

297 × 420 |

353 × 500 |

324 × 458 |

|

-4 |

210 × 297 |

250 × 353 |

229 × 324 |

|

-5 |

148 × 210 |

176 × 250 |

162 × 229 |

|

-6 |

105 × 148 |

125 × 176 |

114 × 162 |

|

-7 |

74 × 105 |

88 × 125 |

81 × 114 |

|

-8 |

52 × 74 |

62 × 88 |

57 × 81 |

|

-9 |

37 × 52 |

44 × 62 |

40 × 57 |

|

-10 |

26 × 37 |

31 × 44 |

28 × 40 |

Source: Standard ISO 216

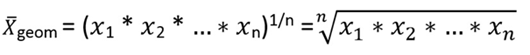

Lets bring an example

of calculating the geometricl mean. First, we look at the formula

The formula is:

We derive the measurements

of B1 through A0 and A1

For example, the geometric mean for the side lengths

841 mm and 594 mm is:

![]() = 706.79 mm ≈ 707 mm

= 706.79 mm ≈ 707 mm

And for the side lengths 1189 mm and 841 mm:

![]() = 999.97 mm ≈ 1000 mm

= 999.97 mm ≈ 1000 mm

Therefore, derived measurements of B1 are 707 x

1000 mm

Geometric mean is usually related

to sequences. In this example, both format sizes were proportionally changed .

This calculation can also be used to

calculate the compromise variant of movie and TV screen size ratios

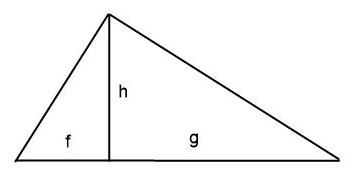

The portrayal of the geometric mean

is also similar to the triangle height formula and would look like this:

![]()

In the drawings letter standards are

also used.

In everyday life, however, we use

thousands of standards that are industry specific, such as standards for

mechanical engineering, the chemical industry etc .

International System of Units

Before the metric system (of measurement) was

introduced internationally, each country was using a different measuring unit

that caused a lot of confusion. Today, most countries have adopted a uniform

international system which has made communication and bureaucratic procedures a

lot easier.

Unified quality standards

Another example is a situation

where we have a different understanding of the quality of a finished product,

detail or building on the local level . Hence, in order to have the same

understanding for all the parties involved, our activities must be based on

quality standards or laws.

Drawings

When familiarizing yourself with the drawings you

first must clarify all the symbols used.

In some drawings and plans (topographical symbols ) symbols are explained .

However, in order to have a better understanding of the drawing, it is useful

to know them in advance.

Different standards are used in construction and

mechanical engineering drawings. Their difference lies in the types of lines,

dimensions and symbols used.

Since constructors must sometimes use drawings for mechanical engineering, it

is useful for them to know the notations and definitions of both standards

Construction

Projects

To define a construction project - it is a set of necessary documents ,

which consists of a letter of explanation, technical drawings , technical

safety instructions, operational and maintenance manuals and other relevant

documents .

Scale

If we look on the mathematical side of

constructional design, scale plays an important role.

Plans are usually "scale drawings", meaning that the plans are drawn

at specific ratio relative to the actual size of the place or object. Various

scales may be used for different drawings in a set.

The scale can be used to either increase or

decrease the real situation. For example, buildings and constructions are

usually so large that in order to portray them on a drawing we must

reduce their measurements and dimensions proportionally.

The opposite situation arises with small details. For

example, to sketch a small screw or a shim it is reasonable to increase its

size on paper to be able to add remarks or measurements on the drawing.

The

length of a line on a drawing or a maps is usually expressed as a fixed value.

The length of the drawn line is chosen to represent a fixed relationship of the

length of the real objekt. Either the number scale, explanatory scale or

topographic linear scale can be used.

In the construction industry, plan and map scale is

used. Corresponding measurement on a project drawing is called plan scale.

Geographical measurements are portrayed as a map scale

Map scale is a ratio which compares a measurement

on a map to the actual distance between locations identified on the map. This

can be used to mark building sizes on a map.

A scale of 1 : 100 means that the real distance is

100 times the length of 1 unit on the map or drawing. (metric scale)

An scale of 1:50 means that 1cm corresponds to 50

cm or 0,5 m.

A

map scaled to 1 : 100 000 means that the real distance is 100 000 times the

length of 1 unit on the map or drawing. At this scale, 1cm on the map represents 1km on the ground and 5cm

represents 5km.

This

result was achieved using the following calculation: 1 km = 100 cm x 1000 cm =

100 000 cm

Types of scales

Number scale

This scale can be used to

calculate lengths on a map or the ground

For

example expressed as a ratio like 1 : 500. This simply means that 1 unit on the map represents 500 units on the

ground.

![]()

Linear scale (bar scale)

A person using the map can use a

pair of dividers to measure a distance by comparing it to the linear scale. The

length of the line on the linear scale is equal to the distance represented on

the earth multiplied by the map or chart's scale.

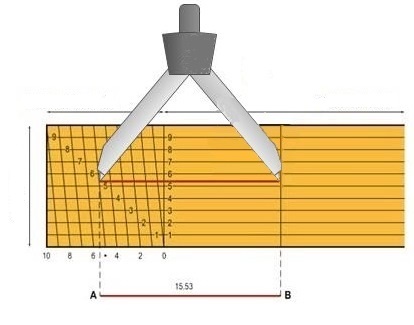

“Transversal” scale

A pair of divders is also needes when using a

transversal scale. An additional option here is to use the hight of the scale,

meaning we can divide the basic units into smaller units – tenths and

hundreds.

Accuracy of a scale

The smallest length shown on maps or plans is 0,2 mm

Excercises

Convert the scale

a. 1

: 10 000

b. 1

cm – 20 km

c. 1

: 500

d. 1

cm – 600 m

e. 1

: 1000

Practice test

(link)

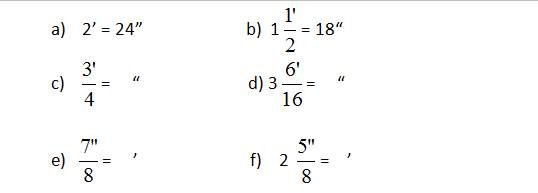

Measuring in inches (imperial system)

Even though we use the SI-system or so

called metric system, in some construction areas the imperial system is used.

On area it is used in quite often is carpentry. It is used for wooden materials

and also for pupes. Their measurments are usually given in inches.

Threfor we’ll look a bit more into the imperial

system

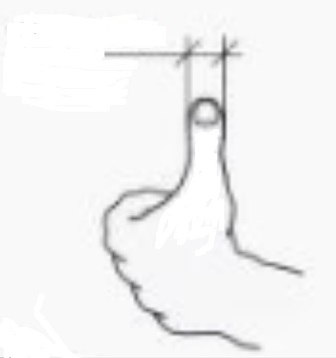

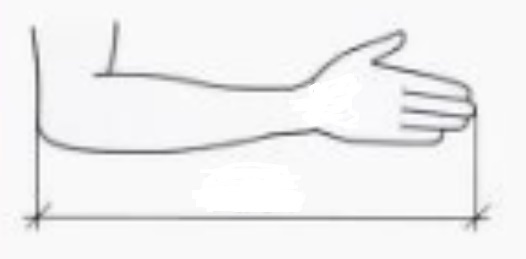

In the old days when the International

measuring standards had not been developed yet, people used their body parts

for measuring. As you can imagine, the size of a body part can be very different

for different people - this caused a lot

of confusion.

For excample the norweigan-danish inch

equaled 26,2 mm but the swedish one 24,7 mm . Also the american and britis

measurments differ.

Nowadays the measurments are set fest

in the following way:

1 inch (1”) = 25,4 mm

1 foot (1’) = 12

inches (12“) = 304,8 mm

1 ell = 21 inches

(21”) = 533 mm

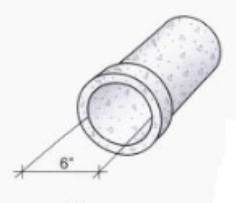

Samples of pipe measurements:

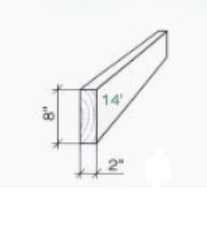

A wooden plank:

Diffences

between the metric and imperiaal system

The international standard symbol for

inch is in but traditionally the inch is denoted by a double prime,

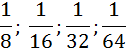

which is often approximated by double quotes. Subdivisions of an inch are

typically written using dyadic fractions with odd number numerators.

In metric system we use the radix point

to separate the integer part of a number

from its fractional part. For example 0,1; 0,01; 0,001 etc.

For example:

If 1 inch (1’’)=25,4 mm then:

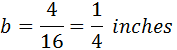

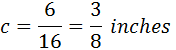

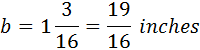

![]() inches =

inches = ![]()

![]() inches =

inches = ![]()

Calculating with fractions

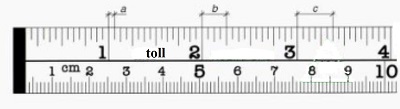

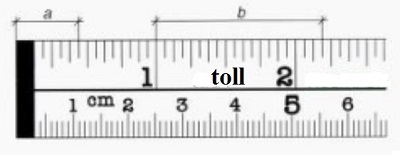

For a better understanding of the

differences between the two system, lets look at the measuring tape. The

measuring tape shows both systems inches and cm.

As mentioned before, the main

difference is that the imperial system uses simple fractions to denote the

subdivisions of an inch. On the portrayd measuring tape, the smallest fraction

is 1/16 of an inch.

The different segments are measured as:

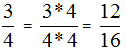

To expand the simple fraction, we

multiply the numerator and denominator with a number

For example

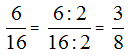

To reduce (or simplify) a single

fraction, divide the numerator and denominator by their Greatest Common Factor

(GCF)

For example

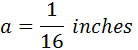

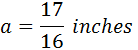

The next drawing:

On this drawing:

![]()

![]()

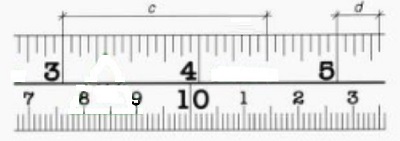

For

example:

Converting feet to inches

1 foot equals 12 inches, then 2´=24´´

![]() gives 24´´+6´´=30´´

gives 24´´+6´´=30´´

With larger values we convert as

follows:

a)

Given ![]() we can write it as

we can write it as ![]()

b) Now we convert feet to inches: ![]()

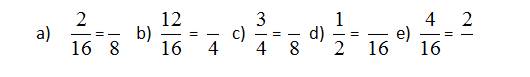

Exercice

1. Reduce

or expand the fractures and fill out the empty spaces

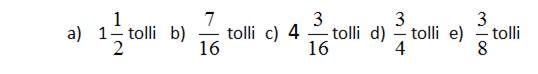

2. Convert

into mm

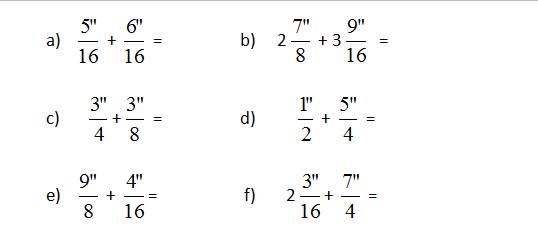

3. Give

the solution in metric system

4. Convert

(feet and inches)